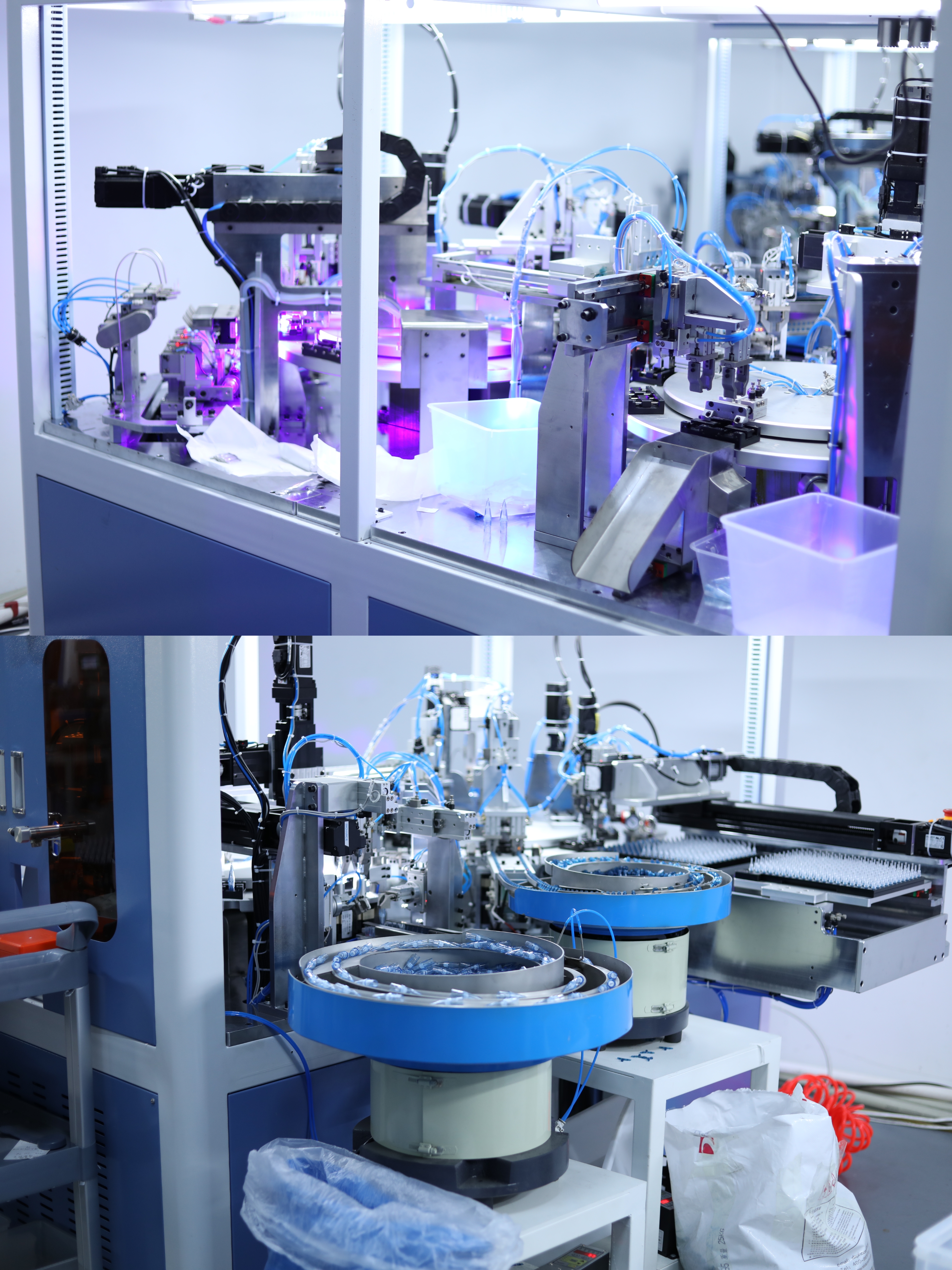

Automation in production brings significant advantages across various industries, and tattoo needle manufacturing is no exception. Here are several key advantages brought about by automation:

-

Increased Production Efficiency: Automated production lines can operate nearly continuously, greatly enhancing production efficiency. Compared to manual production, automation enables faster completion of large orders, thereby shortening production cycles.

-

Reduced Production Costs: By minimizing human involvement, automation lowers labor costs. While the initial investment in automation equipment may be high, in the long run, it reduces the production cost per unit, enhancing the competitiveness of businesses.

-

Enhanced Product Quality: Automation ensures high consistency and precision, reducing the impact of human factors and improving product quality and standardization. This means customers can trust the product quality more, while reducing waste and return rates due to production errors.

-

Improved Safety: Automated production lines can operate under the supervision of safety control systems, reducing workers' exposure to high-risk environments. This helps to minimize workplace accidents and enhances the safety of the production environment.

-

Flexibility and Scalability: Automated systems can typically be adjusted and modified as needed to accommodate different production requirements. This enables businesses to respond more quickly to market changes and customer demands, enhancing flexibility and adaptability.

In summary, automation in tattoo needle production brings higher efficiency, lower costs, better quality control, and a safer production environment, contributing to the advancement and progress of the entire industry.